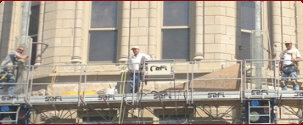

Terra Cotta Repair

Terra Cotta (which means "cooked earth" in Italian)

Terra cotta is a ceramic material that has been used since ancient Roman Times. Terra cotta production in the United States began in 1850 and was primarily used as fire stopping. In 1868 Chicago Terra Cotta Co. began production of architectural terra cotta primarily used on steel framed buildings.

Terra Cotta was widely used as a fireproof building material after the 1871 Chicago Fire. In the late 1800’s it was used for accents on buildings and in the early 1900’s is was used widespread as an exterior cladding material. It was also a low cost alternate to carved stone.

Sources for Common Distress in Terra Cotta

Moisture penetration which causes deterioration of steel, moisture expansion, thermal movements and building movement.

Deterioration of mortar joints that allow water to penetrate the terra cotta.

Cracking caused by corrosion of substrate metals, expansion, and building movement.

There are two types of surface spalls common to terra cotta cladding.

Glaze spalls (loss of surface glaze) Some typical causes include freeze / and thaw cycling, trapped moisture, moisture movement thru the terra cotta and biological growth.

Bisque spalls (clay body) deeper and extend into the body of the terra cotta. Some typical causes include freeze / thaw cycling, corrosion of supports, impurities in the clay.

Crazing fine hairline cracks within the glaze. Crazing occurs when the stress caused by moisture expansion of the clay body exceeds the tensile capacity of the glaze.

Inappropriate repairs typically cause the most severe deterioration to a terra cotta facade. These include replacing mortar with caulking which entraps water, incompatible patching compounds, repointing with hard portland mortar, coatings and the use of aggressive cleaners.

Depending on the condition repairing terra cotta is more complex than most masonry repairs.

Before we estimate a terra cotta restoration project we must assess the amount of damage to the terra cotta. These include visual assessment and documentation, evaluation by sounding the terra cotta with a wood mallet to locate loose or delaminated terra cotta units. If needed, create openings in the facade to evaluate the underlying support structure and determine the causes of the terra cotta distress. There are other methods of evaluation, but too many to list here. Masonry Construction Inc. has repaired terra cotta projects in Omaha, Ord and Fall City NE.

We use the finest terra cotta repair products that are available. Our product of choice for terra cotta repairs - Edison Coating Products. They are completely compatible, breathable and customized for each individual building. We repair terra cotta by using patching mortars and then installing a glazed finish over the terra cotta. Terra cotta can have slight color changes thru out the building due to exposure to the elements. During the application of the Aquathane or glaze finish we can adjust color to match the variations in the existing terra cotta.

Our Repair Products:

Bisque spalls - Custom 45

Small chips - Thin Fill 55

Crazing - Elastowall 351 permanently flexible, breathable masonry coating designed to waterproof and can be applied over a wide variety of previous coatings, treatments and patches.

Glaze finish - Aquathane Type E - high performance water born polyurethane based coating.